Measurements of leaks

Parts that are leak-tight are not always good! Our leak test systems measure intended leaks with a defined minimum and maximum limit.

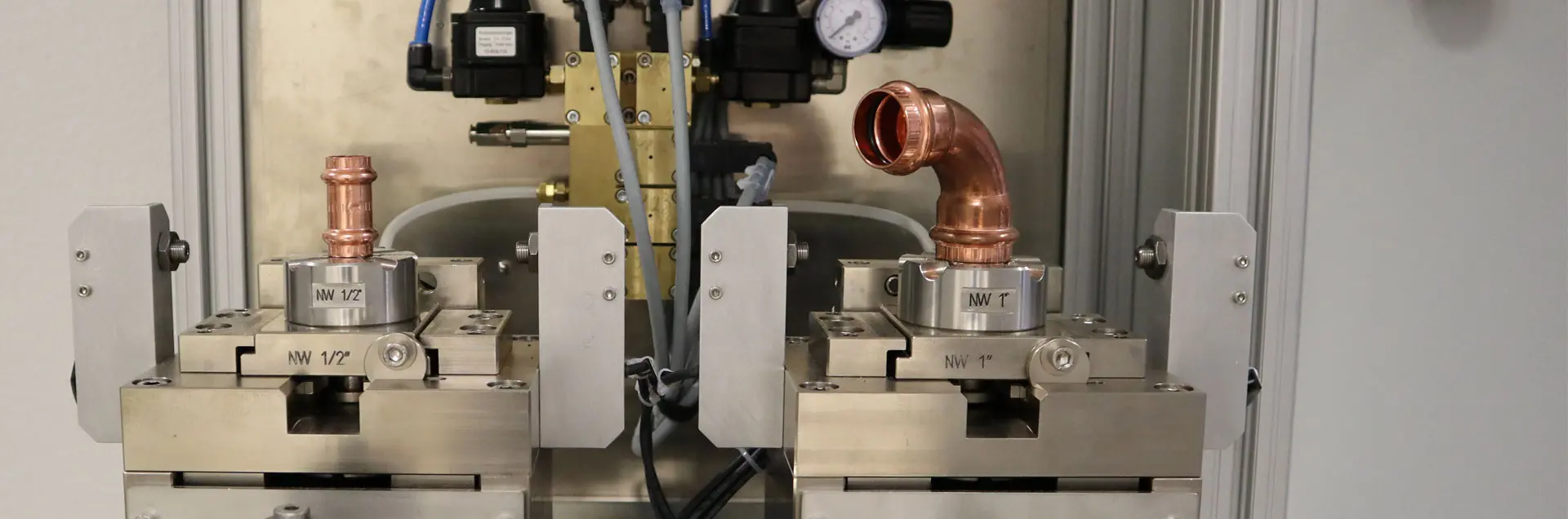

An application example are for fittings of different nominal sizes, which are used in the field of gas and water installation in order to reliably detect leakage in a non-pressed fitting in a piping system. Thereby, the leak is not only detected by measurement, but also localized through an acoustical noise at high pressure.

Apart from the minimum leak the presence of an earlier assembled o-ring can be tested as well.

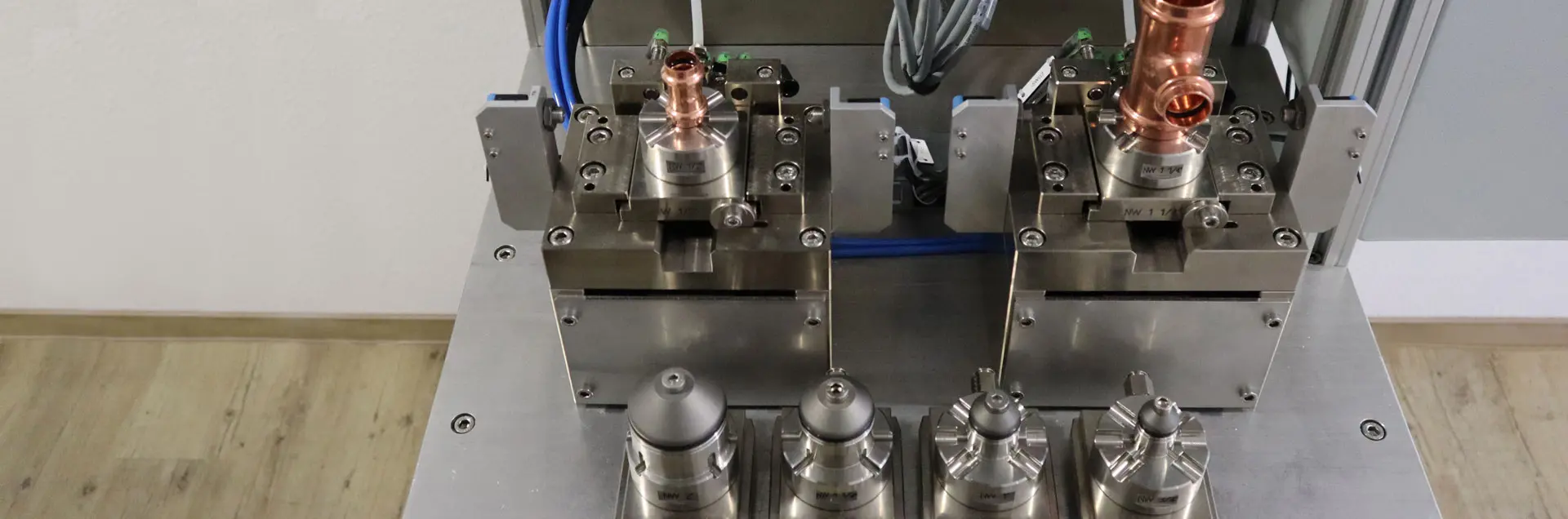

The system consists of two test devices as to test fittings with different nominal sizes; switching to the respective test device takes place automatically.

Interchangeable device parts, those dependent on workpiece nominal size, can be fitted quickly and are provided with clear mechanical coding so that the test program matching the nominal size is automatically called up. An incorrect program selection by the operator cannot take place.

Integration into existing customer systems is possible. The superior PLC is able to start the test process and handle the automated loading and unloading of the fittings.

- Scope of size:½", ¾", 1", 1 ¼", 1 ½", 2" u.v.m.

- Workpiece transport:Manual loading and unloading

- Cycle time:10 s

- Number of processes:Detection of a leak in non-pressed fittings, at high pressure: <0,5 l/ min, at low pressure: <0,5 l/ min

- Required personnel:1 employee for loading and unloading

- Easy use:Automatic selection of the corresponding test program by coded mechanic interchange parts of workpiece nominal size in the device