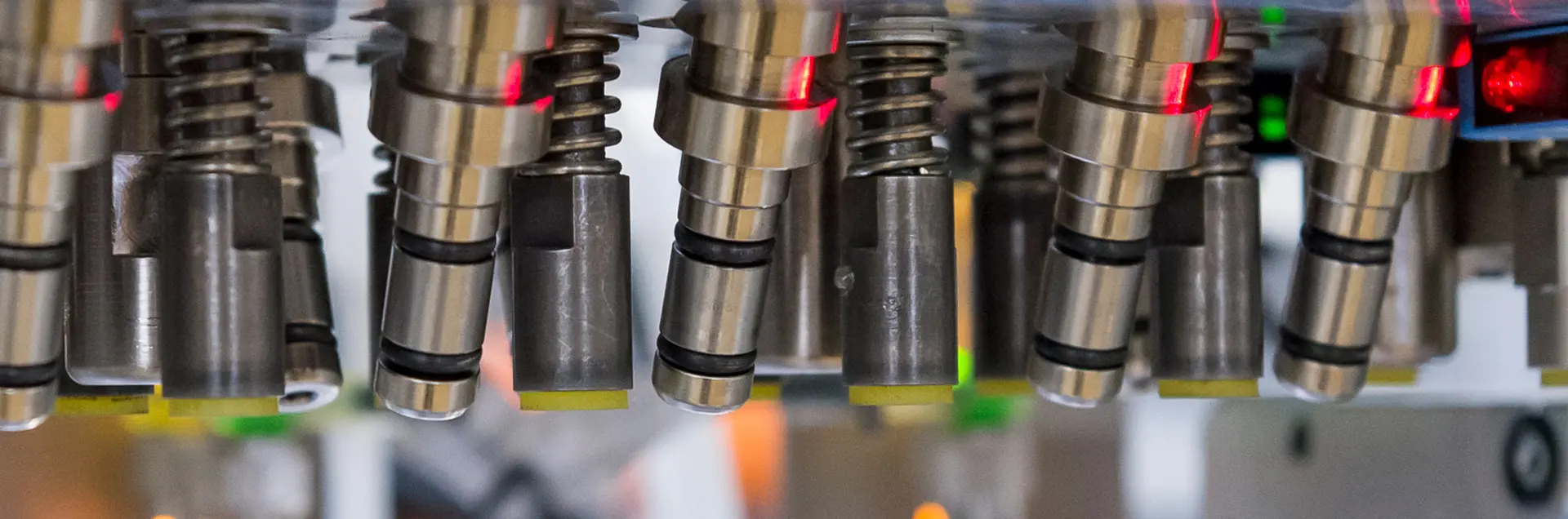

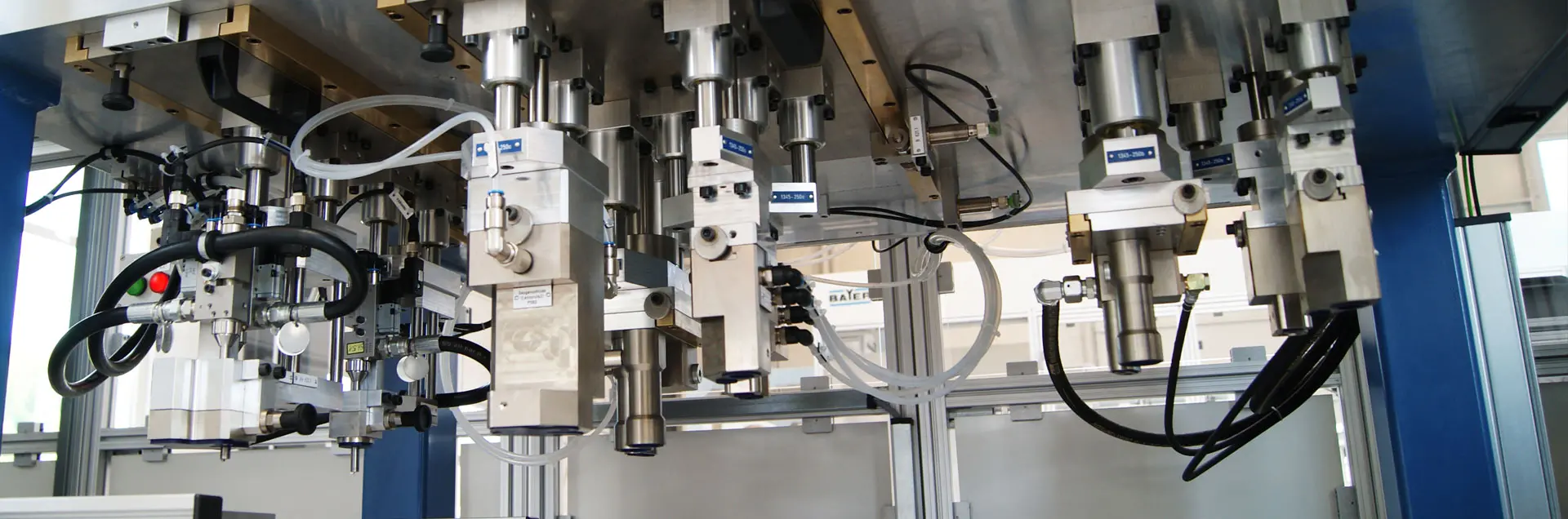

Typical tests for valves are hot switching, simulated manual switching, automatic switching by applying the supply voltage or a volume-time test, in which the valve is filled to a certain pressure in different switching positions within a certain time and then vented. Leak tests are often also carried out in the various switching positions in order to assign leak tightness classes according to the measured leakage rate.

A multitude of different process competencies

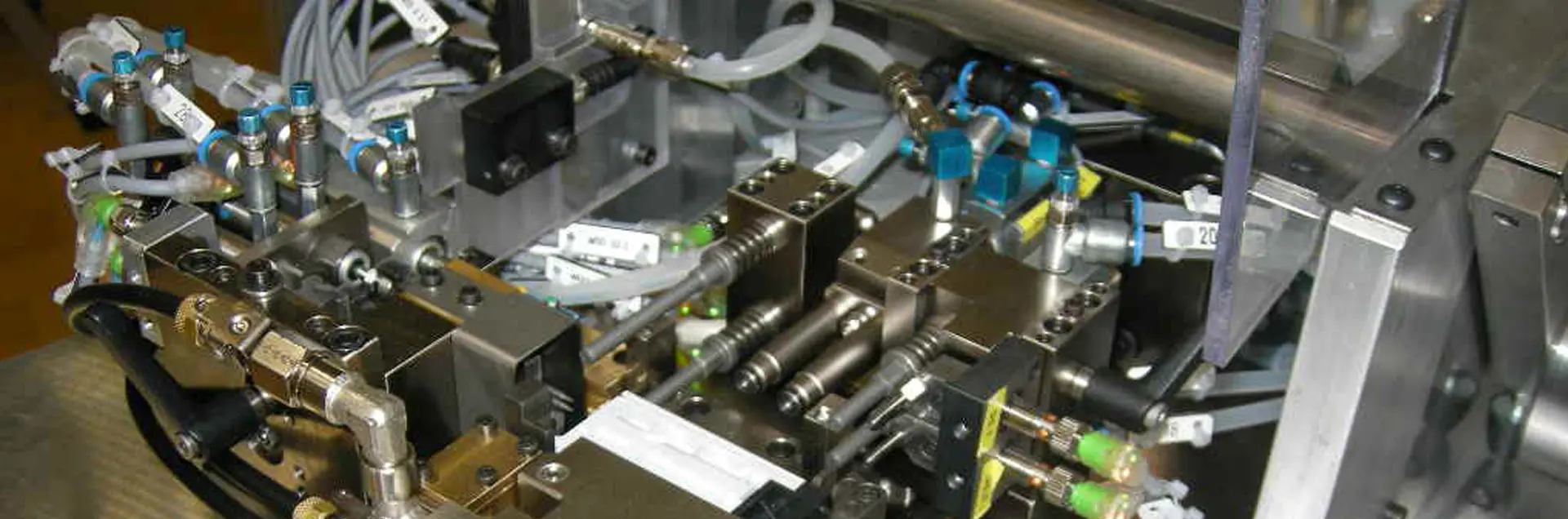

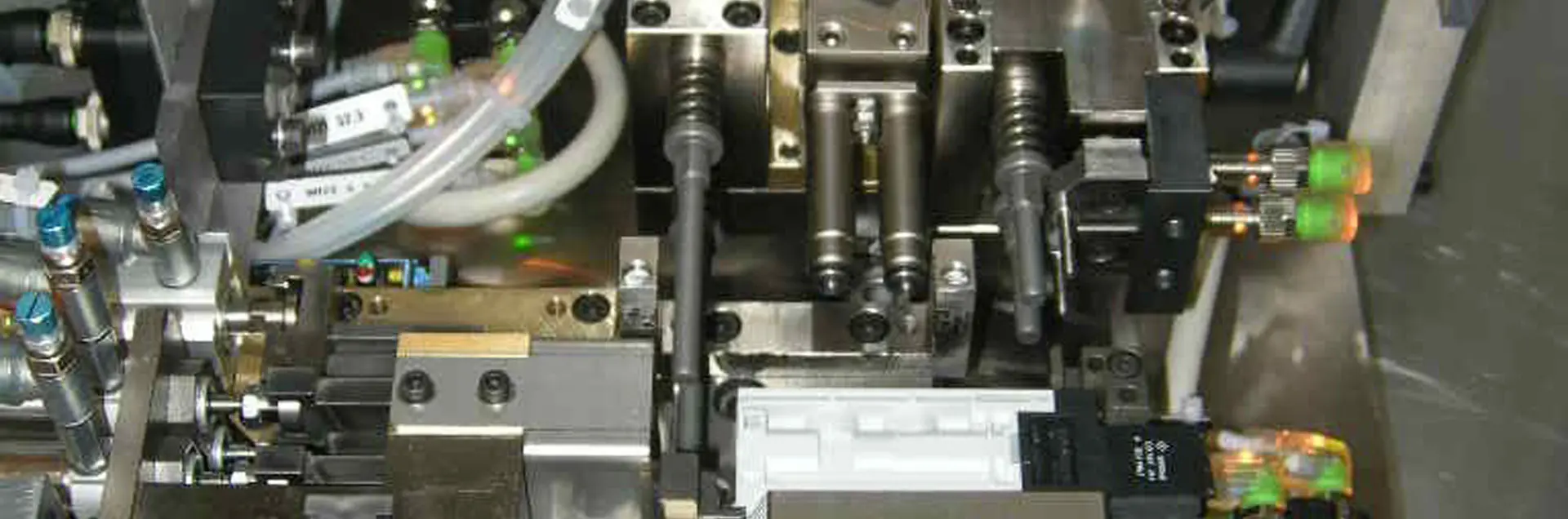

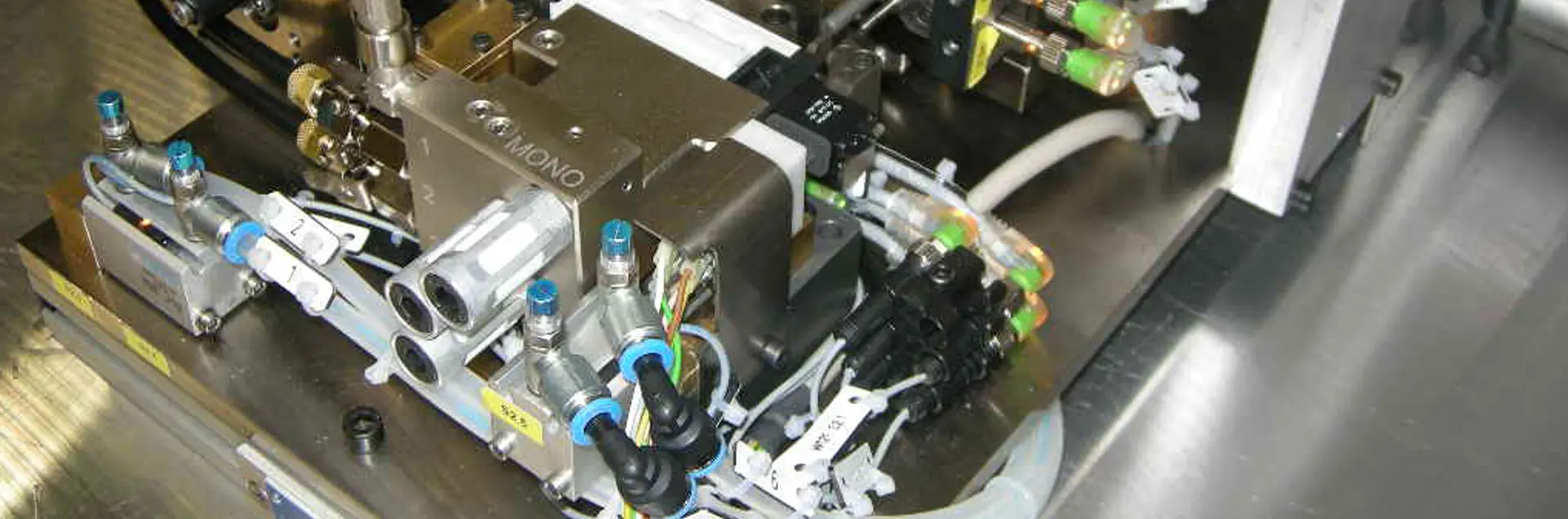

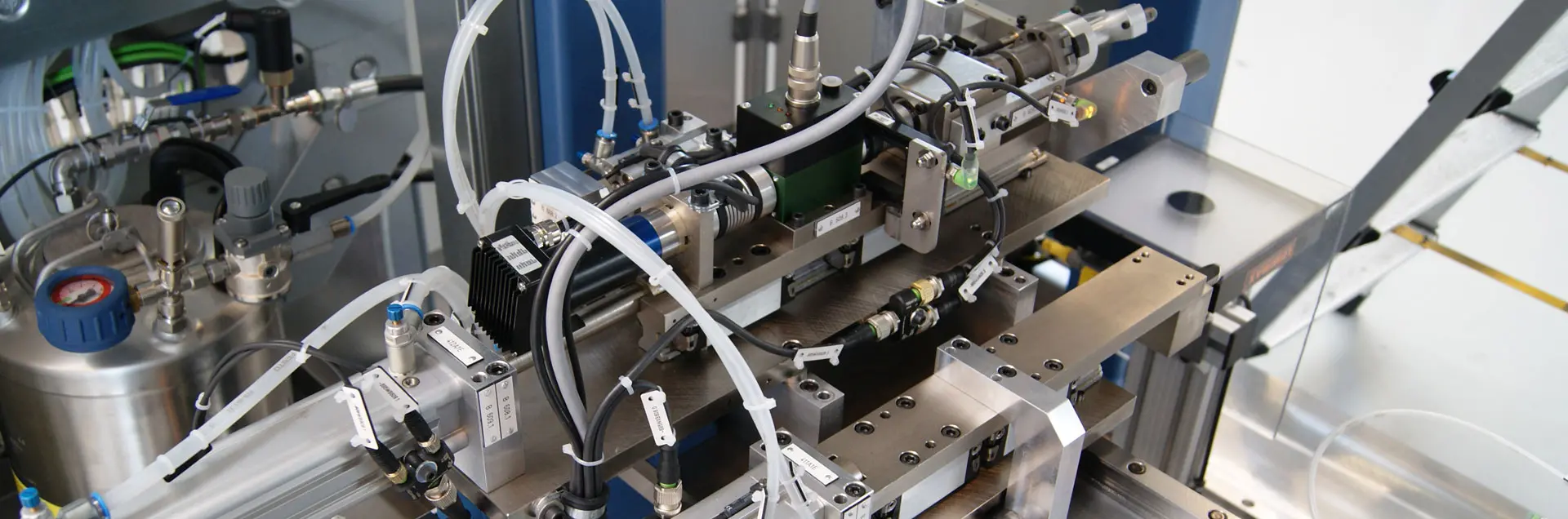

We are able to integrate a large number of processes into our machines and automate them to the extent required. Various processes, such as function and leak tests, joining, gluing or screwing operations can be implemented using our integrated machine concepts. We are constantly expanding the range of controlled processes. The latest process we have acquired is friction stir welding.

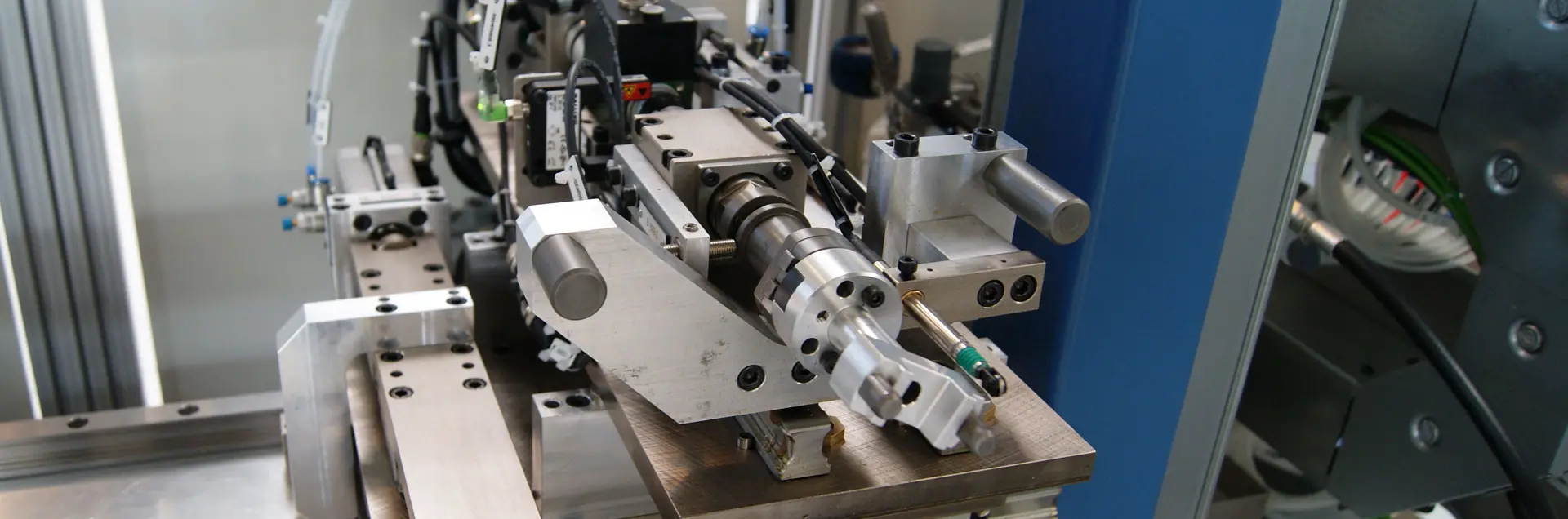

We can also test products that we have assembled. A functional test often takes place after the assembly of a functional unit in a subsequent work step as a final test (end-of-line). Examples of workpieces on which functional tests have been carried out are pumps and valves.

Many parameters can be tested in the case of pumps. Be it mechanical properties, such as ease of movement and axial run-out or performance data, such as built-up pressure, flow rate and speed. All collected data for a pump are displayed in a service life file.