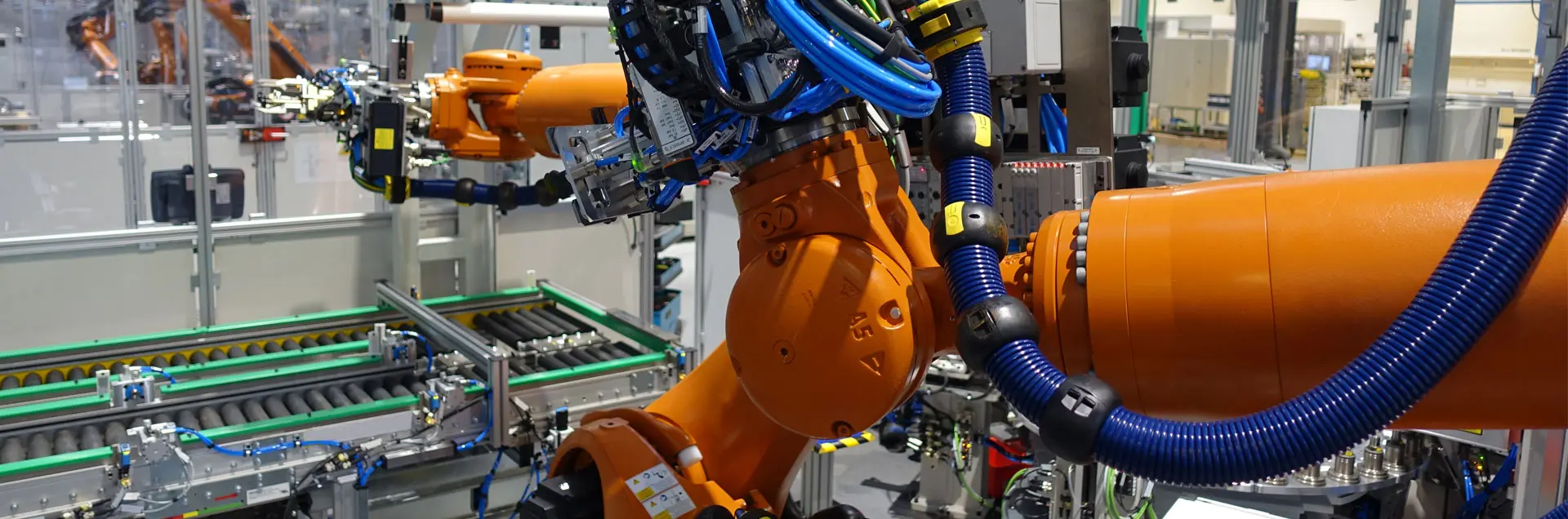

Innovative automation concepts for tripod star support assembly

Cross-brand platform strategies and optimisation of product portfolios e-mobility and SUVs lead to greater product diversity and new dimensions. The demand for flexibility and ergonomics is growing in terms of machine concept and operation. Using innovative automation approaches, we will help you accelerate the transformation for processes.

The assembly of tripod star supports, which are the most efficient form of constant velocity joints have the lowest friction values and transmission from the wheel to the vehicle, is a special part of the beginning transformation process. We meet quantity, part size and precision requirements with a unique combination of solid mechanical engineering, precision tool making and innovative machine concepts. Reliability, availability and ease of maintenance are a priority for you and for us.

1,500,000 bearing needles and 40,000 swivel castors per day are assembled by our machine. Our teams from Research and Development, Mechanical and Electrical Design, Programming, Manufacturing and Assembly are happy to implement the know-how gained over decades of solving such challenges for you.

- Number of assembled components:Outer ring (3x), needle roller (120x), locking part (3x), snap ring (3x)

- Variety of types/complexity:2 workpiece types

- Workpiece transport:Feeding via blister by pallet conveyor then loading onto the rotary table by robot, followed by unloading by the same robot

- Cycle time:≤ 9 s

- Number of processes:Insert outer rings, insert needles, assemble locking part and snap ring, laser clear text

- Required personnel:0 employees, provide assembly parts as bulk material and refill process media

- Checked parameters (characteristics:Completeness of needles, correct fit of locking part and snap ring